We turn ideas into realities.

We're here to help. In the initial consultation, we'll walk you through the steps necessary to get your project accomplished.

Our project managers handle the engineering scheduling, resource allocation, budgeting and design plan, leaving you more time to grow your company.

Tap into our network of engineers, technicians, designers, distributors and manufacturers for a superior product, without the worry.

With a history of successful project completion, we understand what it takes to get your project completed, quickly and efficiently.

Experience gained from past projects.

We recommend all of our customers get quotes with other development firms. We can all use a good laugh every once in a while.

Our customers need a working prototype yesterday. With a library of customizable assets, we have a proven track record of fast deliveries (typically 1-3 months).

Not a single unhappy customer, 100% succes rate. Just ask our clients. Recommendations available upon request.

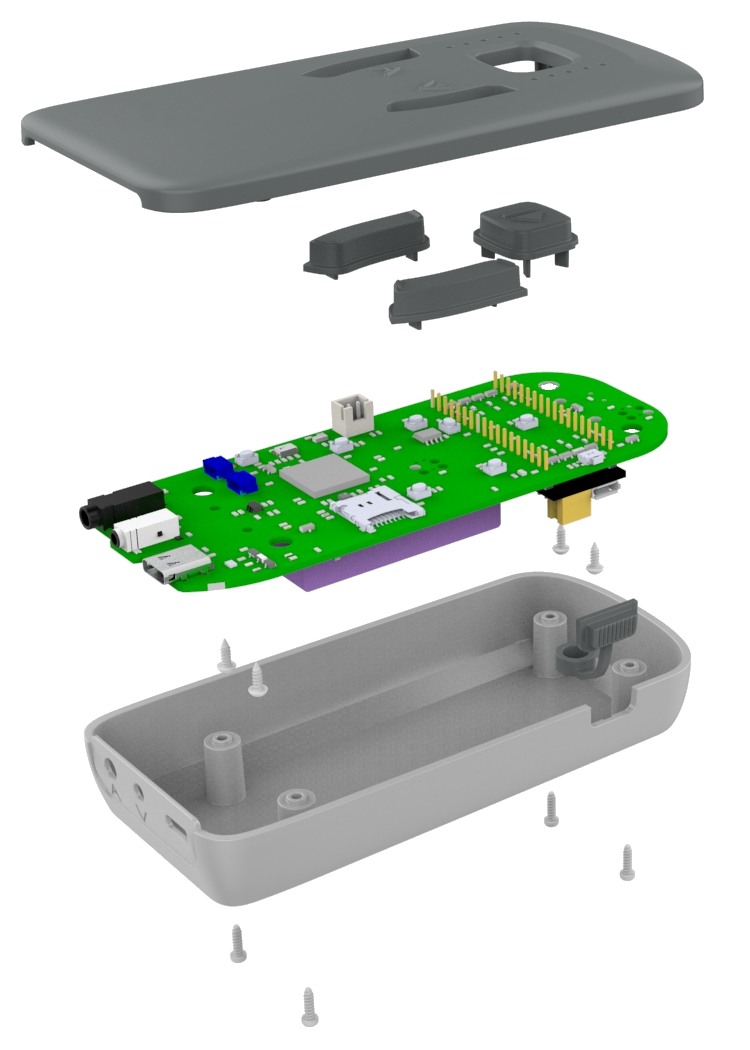

Our bread and butter. Countless successful deliveries of microcontroller-based designs and the accompanying firmware.

Cross-platform (iOS, Android, etc.) smart-device apps with modern development environments for tantalizing user-experiences.

A design is only as good as the people that make the product. We have a vast production and sourcing network cultivated over the years. Leverage our connections to optimize your mass-production strategy.

We like to think of a project from a top-down approach. Unlike the traditional philosophy of leveraging in-house engineers, designers and integrators to produce a new product, we believe that a team should be assembled specifically based on their talents. We go straight to the source of the knowledge.